The Clean Room is an essential requirement for opening hard drives and intervening in their interiors.

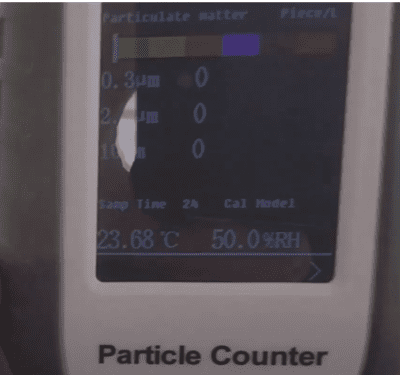

Real particle measurement inside our Clean Room. ZERO! :)

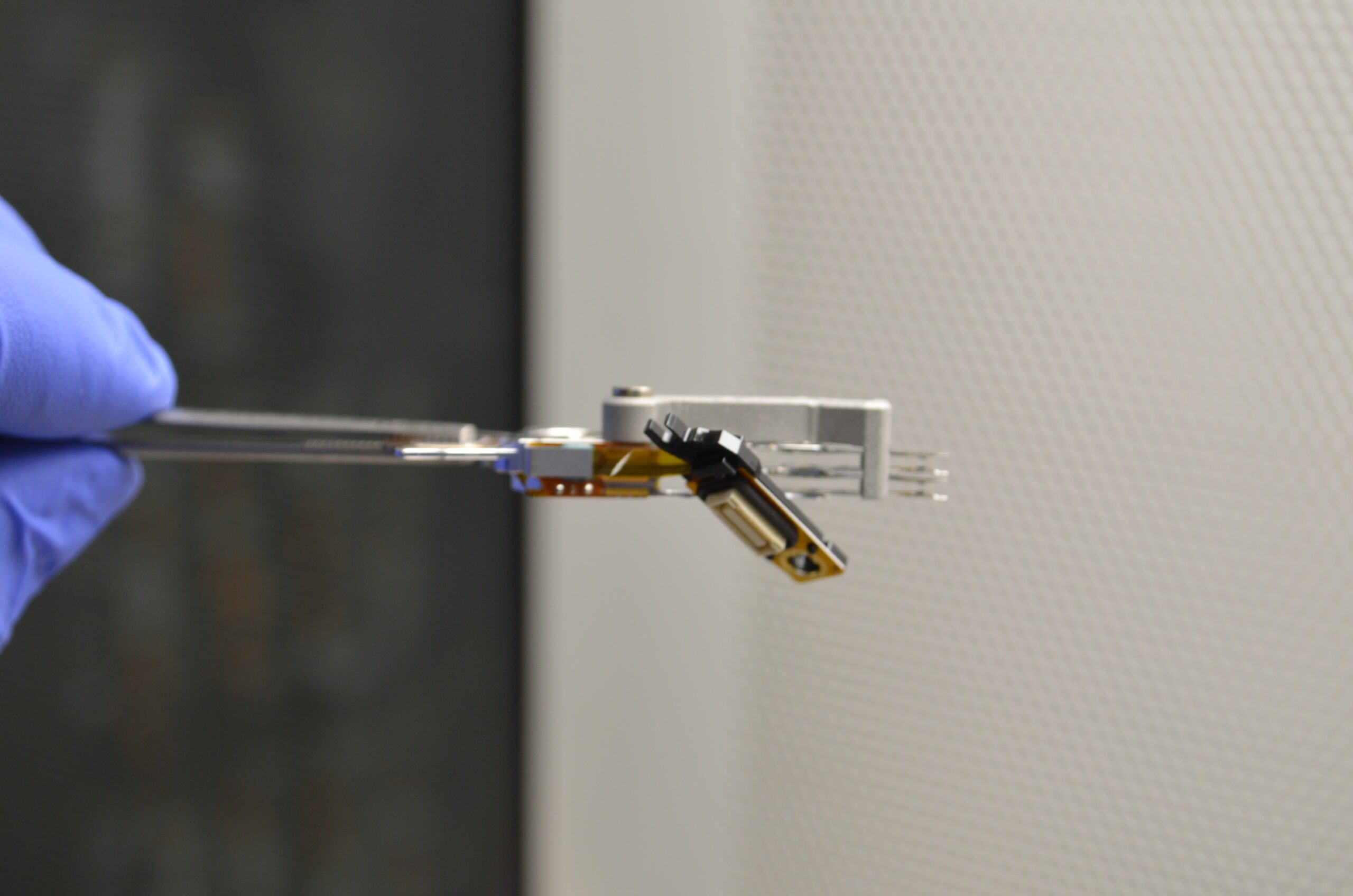

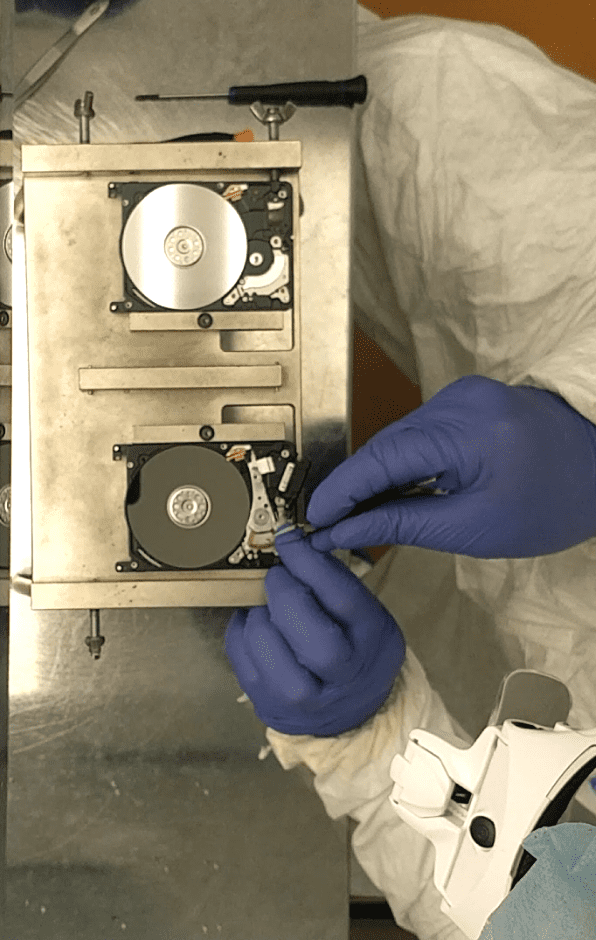

For failures requiring mechanical intervention (damaged heads, stuck motor, stiction) and even for visual inspection of the hard drive, opening in the Clean Room is required.

The Clean Room is free from dust and moisture particles, making the opening of drives safe. This is because the ingress of particles into the interiors of the drives can be catastrophic for the heads, surface, and data, as the height at which the heads “fly” is much smaller than the height of a dust particle!

For this reason, the “class 100” protocol has been established in Clean Rooms. Class 100 means that up to 100 particles with a diameter <0.5μm per cubic foot of air are allowed. For comparison, we note that a human hair has a diameter of approximately 75μm.

At Northwind Data Recovery, besides the unique large-sized Clean Room, we use the 1000/100/10 method. The anteroom of the Clean Room has a Class-1000 specification, which means that it is designed for 1000 allowable particles per cubic foot of air.

The main chamber has 10 times stricter specifications with 100 allowable particles, while the Clean Box where mechanical interventions are made allows up to 10 suspended particles, ten times less than the stipulated amount. In practice, our measurements show that our filters do an excellent job and the suspended particles inside our Clean Room are zero!

See here an experiment we did, exposing a hard drive to dust outside the Clean Room. Our experiment confirms the theory.

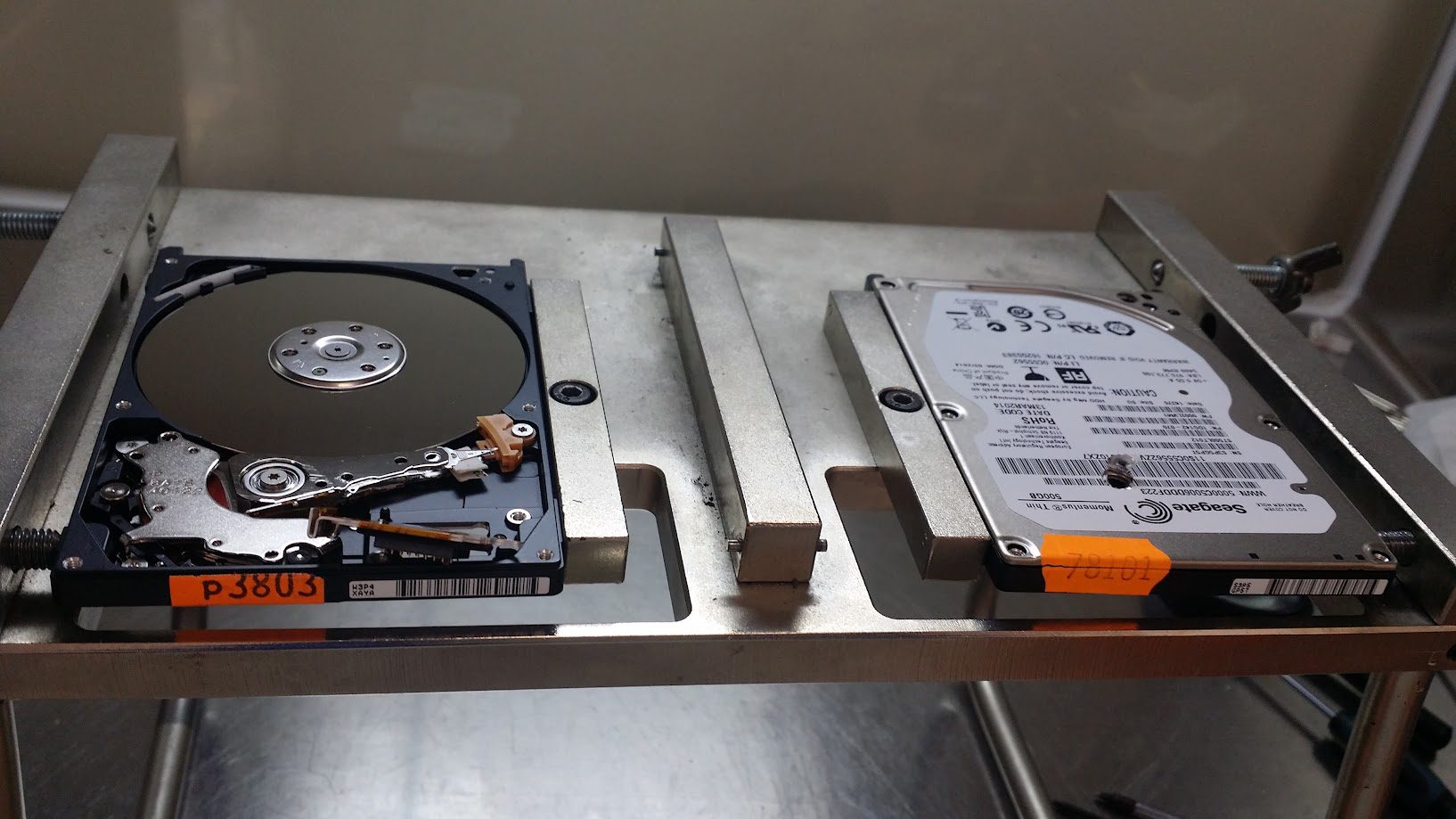

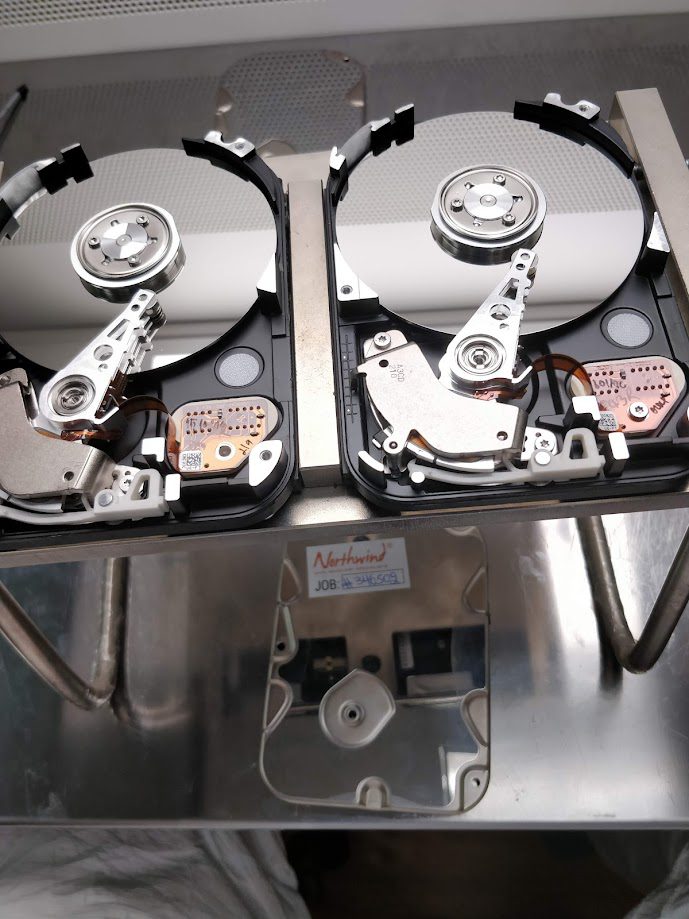

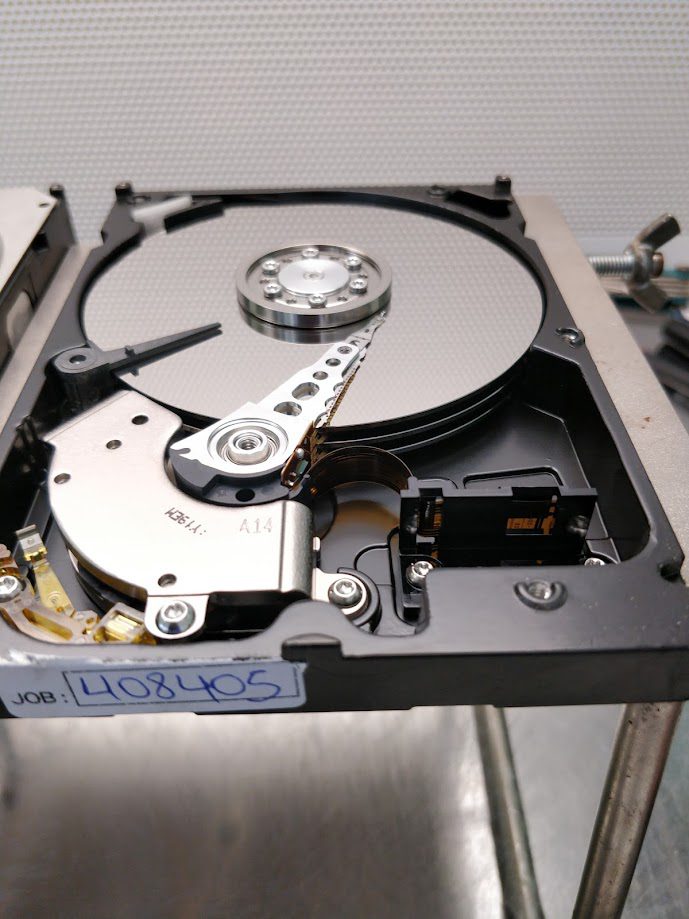

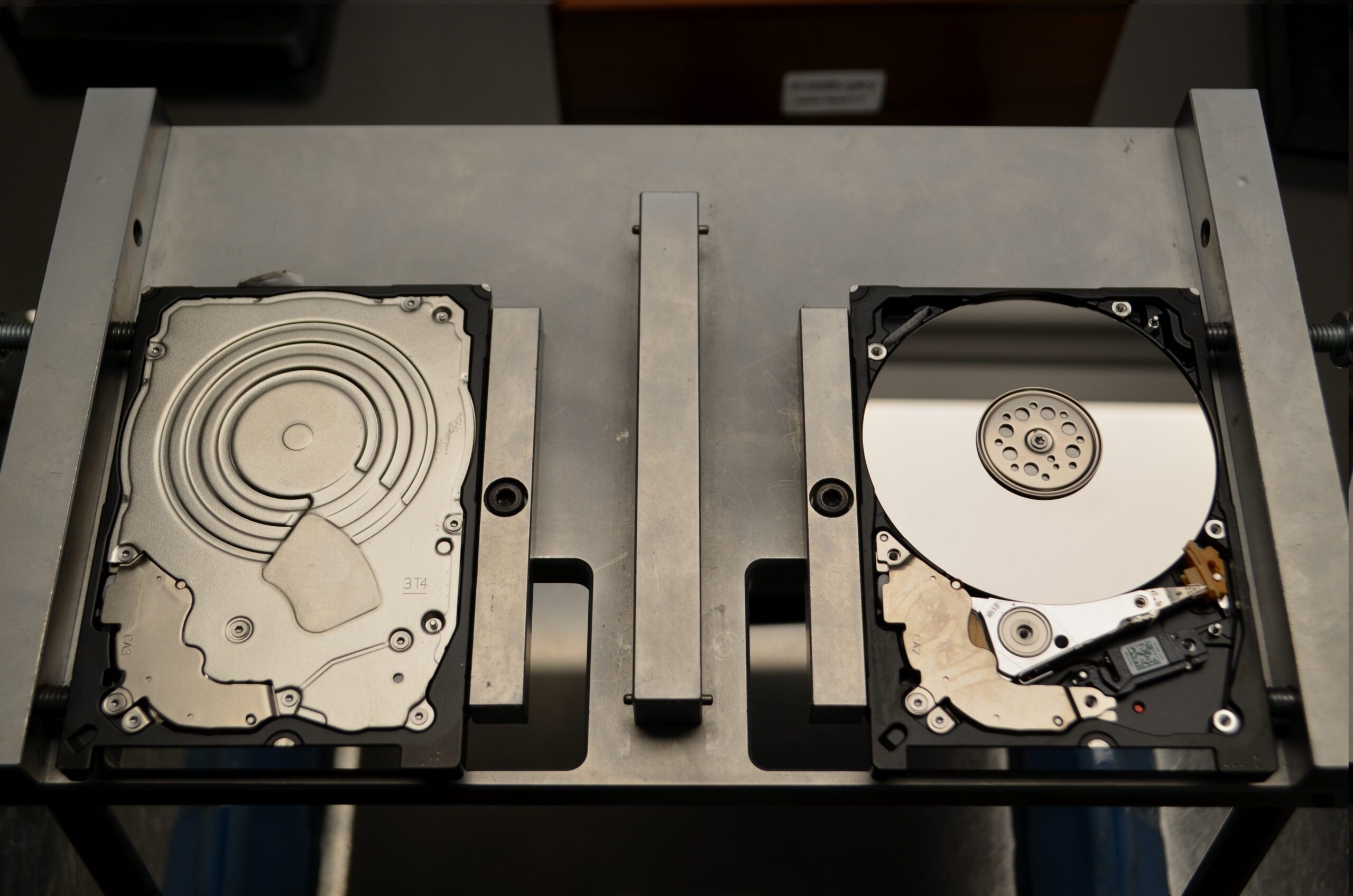

Below you can see some indicative photos from inside the Clean Room.